5 Ton Overhead Crane

5 Ton 13.8m H-6.3M Single Girder Overhead Crane with Electric Wire Rope Hoist for Sale to Nigeria

Lifting Capacity: 5 ton

Span: 13.8 m

Lifting Height: 6.3 m

Working Class: A3

Note: We can design and manufacture the crane according your requirments and working conditions.

5 Ton 13.8m H-6.3M Single Girder Overhead Crane with Electric Wire Rope Hoist for Sale to Nigeria:

We successful sale and delivery of a 5 Ton Single Girder Overhead Crane with Electric Wire Rope Hoist to our esteemed customer in Nigeria.

Initial Inquiry & Customer Requirements

The sales process began when a Nigerian client from the manufacturing sector contacted us with specific material handling requirements. After understanding their operational environment and lifting needs, we recommended the LDA Model 5 Ton Single Girder Overhead Crane — a cost-effective and reliable crane system for light to medium-duty operations.

Key requirements included:

Lifting capacity of 5 tons

Compact design to fit an existing workshop layout

Efficient and safe lifting mechanism

Power compatibility with Nigeria’s industrial supply standards (380V, 50Hz, 3-phase)

Technical Specification of the Delivered Crane

- Crane Type: LDA Single Girder Overhead Crane

- Lifting Capacity: 5 Ton

- Span: 13.8 Meters

- Lifting Height: 6.3 Meters

- Working Class: A3 (suitable for general maintenance and moderate load frequency)

- Power Supply: 380V, 50Hz, 3 Phase (standard for Nigerian industrial facilities)

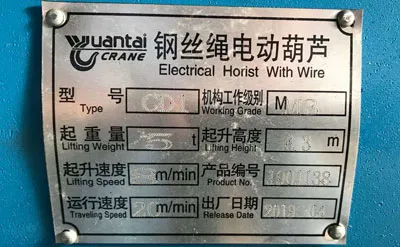

Electric Hoist Details:

- Hoist Type: CD1 Electric Wire Rope Hoist

- Lifting Speed: 8 m/min

- Traveling Speed: 20 m/min

This configuration ensures smooth, safe, and efficient handling of materials within the facility.

Custom Engineering & Production

Once the Nigeria client approved the technical proposal and layout drawings of 5 ton overhead crane, we moved forward with production. Our engineering team customized the span and lifting height to fit their workshop’s layout, ensuring optimal usage of floor space and lifting height.

The 5 ton overhead crane was fabricated using high-quality steel and was coated with anti-corrosion paint to suit Nigeria’s industrial and environmental conditions.

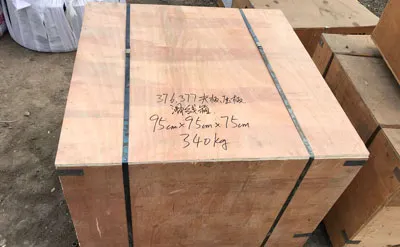

Packaging & Shipping

Upon completion, the 5 ton overhead crane components were carefully packed and loaded into containers suitable for overseas transport. Our logistics team coordinated with the client to ensure a smooth shipping process to the designated Nigerian port.

The 5 ton overhead crane is now fully operational, contributing to increased efficiency and safer lifting operations at the customer’s facility.

Processing of 5 Ton Single Girder Overhead Crane with Electric Wire Rope Hoist for Sale to Nigeria:

Package of 5 Ton Single Girder Overhead Crane with Electric Wire Rope Hoist for Sale to Nigeria:

Optional Add-ons for 5 Ton Single Girder Overhead Crane:

- Anti-Sway Control System: Reduces load swing during travel and hoisting, enhancing safety and positioning accuracy.

- Variable Frequency Drive (VFD): Enables smooth acceleration and deceleration, reduces mechanical stress, and improves energy efficiency.

- Wireless Remote Control: Allows operators to control the 5 ton overhead crane from a safe distance, improving mobility and visibility.

- Cabin Control: Enclosed operator cabin with ergonomic controls for large or high-duty operations.

- IoT Monitoring System: Real-time data tracking for maintenance, usage analytics, and performance diagnostics.

- Overload Protection System: Prevents lifting loads beyond the rated capacity, ensuring safety and prolonging equipment life.

- Explosion-Proof Components: Suitable for hazardous environments like chemical plants or oil refineries.

- Extended 5 Ton Overhead Crane Span or Lifting Height: Customizable dimensions to suit unique factory or warehouse layouts.

- Additional Hoist Speeds: Multiple hoisting speed options for fine load handling or faster cycle times.

- Automatic Lubrication System: Reduces wear and maintenance time by auto-lubricating moving parts.

- Sound and Light Alarm System: Enhances operational safety by alerting nearby personnel during 5 ton overhead crane movement.

- Custom Paint and Branding: Match your corporate colors or apply protective coatings for specific environments.

- Soft Start/Stop System: Minimizes shock loads and increases the lifespan of mechanical components.

- Limit Switches for Travel and Hoist: Prevents over-travel in all directions, enhancing safety and control precision.

Why Choose Our 5 Ton Single Girder Overhead Crane:

- Robust and Reliable Design: 5 ton overhead crane built with high-quality steel and precision-engineered components to ensure durability and long service life.

- Customizable to Your Needs: Tailor span, lifting height, speed, and control systems of 5 ton overhead crane to match your exact operational requirements.

- Compact and Space-Efficient: Single girder construction of 5 ton overhead crane allows for low headroom and optimal space utilization in tight environments.

- Smooth and Efficient Operation: 5 ton overhead crane equipped with advanced motors and drive systems for stable, quiet, and energy-saving performance.

- Multiple Control Options: Choose from pendant control, wireless remote, or cabin operation to suit your working conditions.

- Easy Installation and Maintenance: Modular components and user-friendly design reduce installation time and simplify ongoing maintenance.

- Compliance with International Standards: Designed and manufactured in accordance with ISO, CE, and FEM standards for safety and quality of 5 ton overhead crane.

- Cost-Effective Solution: Provides reliable lifting performance at a competitive price, offering excellent return on investment.

- Expert Support and Service: Backed by experienced engineers, technical support, and training programs from design to commissioning.

- Energy Efficient Systems: Low power consumption motors and optional VFDs help reduce operating costs.

- Versatile Applications: 5 ton overhead crane suitable for a wide range of industries including manufacturing, warehousing, logistics, and more.

Installation of 5 Ton Single Girder Overhead Crane:

- Site Assessment and Preparation: Initial inspection of the site to verify structural readiness, runway beam alignment, and support conditions.

- Foundation and Runway Setup: Install or verify the crane runway beams, columns, or rails as per design specifications for accurate 5 ton overhead crane travel.

- Delivery and Unloading: 5 ton overhead crane components (girder, hoist, end carriages, control panel, etc.) are safely delivered and unloaded at the installation site.

- Assembly of Main Girder and End Carriages: Connect the single girder to end trucks using high-strength bolts and align for proper balance and structural integrity.

- Hoist Installation: Mount the electric hoist onto the girder and secure all mechanical fasteners, ensuring proper alignment with the trolley path.

- Electrical Wiring and Control Setup: Connect all electrical components of 5 ton overhead crane, including control panels, limit switches, motors, and power supply systems.

- Control System Configuration: Install pendant, remote, or cabin controls and test signal transmission and response.

- Mechanical Alignment and Testing: Check wheel alignment, rail gauge, and ensure 5 ton overhead crane smooth travel along the runway. Verify hook centralization and load chain/wire rope routing.

- Safety Feature Verification: Test emergency stop functions, overload protection, limit switches, and anti-collision devices (if applicable).

- Load Testing: Conduct static and dynamic load tests as per industry standards (typically 125% of rated capacity) to ensure 5 ton overhead crane operational reliability.

Shipping of 5 Ton Single Girder Overhead Crane with Electric Wire Rope Hoist for Sale to Nigeria:

Application of 5 Ton Single Girder Overhead Crane in Nigeria:

In light of Nigeria’s ongoing push for industrialization, local manufacturing, and infrastructure development, the **5 Ton Single Girder Overhead Crane** offers a highly practical and cost-effective solution for lifting and material handling needs across key sectors. 5 ton overhead crane's compact design and affordability make it especially suitable for businesses adapting to economic pressures while aiming for productivity.Key Applications in Nigeria:

- Manufacturing & Assembly Plants: 5 ton overhead crane supports lifting of machine parts, tools, and semi-finished goods, boosting efficiency in sectors like steel fabrication, automotive, and equipment manufacturing in Nigeria.

- Warehouses & Logistics Centers: Facilitates fast and safe loading/unloading of goods and palletized cargo, 5 ton overhead crane improving warehouse throughput with minimal manpower.

- Agricultural Processing Facilities: 5 ton overhead crane useful in lifting packaged produce, bags of fertilizer, and mechanical components in agro-processing industries in Nigeria.

- Construction & Building Materials: 5 ton overhead crane ideal for handling steel bars, cement molds, pipes, and precast concrete elements in Nigeria’s growing construction sector.

- Oil & Gas Supply Chain: 5 ton overhead crane efficient for small-to-medium-scale lifting in support facilities, such as pipe yards, workshops, and logistics hubs related to the oil and gas industry in Nigeria.

- SMEs and Local Workshops: 5 ton overhead crane perfect fit for small and medium enterprises in Nigeria looking for affordable automation to improve safety and output, especially in regions with limited space and resources.