10 Ton Overhead Crane

10 Ton 19.85m and H-12m European Type Single Girder Overhead Crane for Sale to Philippines

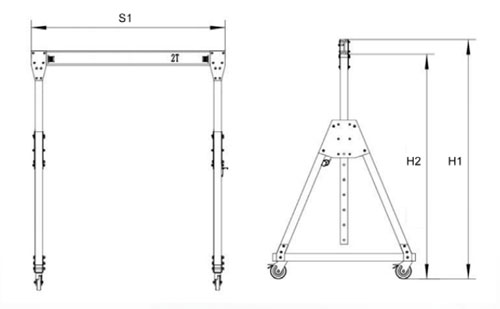

Lifting Capacity: 10 ton

Span: 19.85 m

Lifting Height: 12 m

Working Class: A5

Note: We can design and manufacture the crane according your requirments and working conditions.

10 Ton 19.85m and H-12m European Type Single Girder Overhead Crane for Sale to Philippines:

Specifications:- Lifting Capacity: 10 Tons

- Lifting Height: 12 meters

- Span: 19.85 meters

- Power Supply: 220V / 60Hz / 3 Phase

- Hoist: European Type Electric Wire Rope Hoist

- Control System: Dual-mode (Pendant Control + Remote Control)

Philippine Steel Fabrication company. initiated a procurement process to upgrade its lifting capacity in the main fabrication plant. After technical consultations and a comparative review of quotations, We are selected as the supplier for a high-performance 10 ton European-type single girder overhead crane.

A sales agreement was signed, detailing specifications, payment terms, and delivery schedule. The 10 ton overhead crane, designed with a span of 19.85 meters and a lifting height of 12 meters, met the Philippines customer’s dimensional and operational requirements. 10 ton overhead crane ideal for medium-heavy lifting tasks within the assembly line.

Control System:

The dual-mode control (pendant + remote) was a critical factor in the selection, providing flexible operation both from the ground and at a distance for enhanced safety and productivity of 10 ton overhead crane.

After-Sales Support:

our company offered a 12 month warranty from the date of commissioning and committed to providing remote technical support and spare parts availability for up to 10 years for Philippines customer.

Status:

The 10 ton overhead crane was successfully shipped. and our cmpany technical team providing remote assistance during commissioning Philippines customer.

This transaction marks the first collaboration between the two companies and has opened opportunities for further equipment upgrades in the Philippines client’s expanding operations.

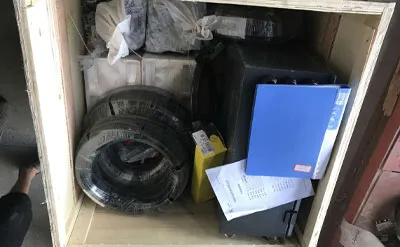

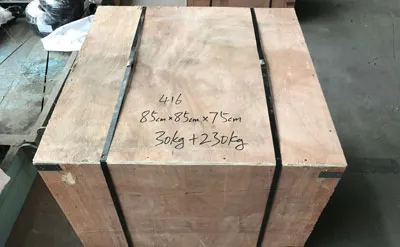

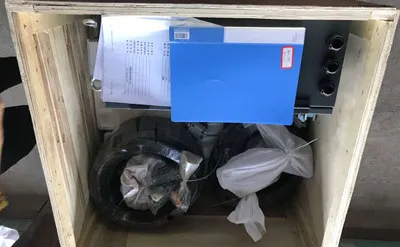

Packing of 10 Ton European Type Single Girder Overhead Crane for Sale to Philippines:

Shipping of 10 Ton European Type Single Girder Overhead Crane for Sale to Philippines:

Top Benefits of a 10 Ton Single Girder Overhead Crane in Steel Manufacturing:

- Efficient Material Handling: A 10 ton single girder overhead crane can effortlessly lift and move heavy steel components such as plates, beams, and coils, improving workflow and reducing manual labor dependency.

- Cost-Effective Design: 10 ton single girder overhead crane are more affordable in terms of initial investment, installation, and maintenance — ideal for mid-range lifting applications in steel plants.

- Space Optimization: 10 ton single girder overhead crane have a more compact design, requiring less headroom and allowing for efficient use of vertical space, which is crucial in steel workshops with limited clearance.

- Enhanced Safety: 10 ton overhead crane equipped with modern control systems like pendant and remote controls, operators can handle materials from a safe distance.

- Improved Production Speed: 10 ton single girder overhead crane covers large working areas, the crane helps speed up the movement of raw materials and finished steel products, reducing delays in the manufacturing process.

- Flexibility in Application: Whether for loading/unloading, transferring materials between stations, or feeding production lines, 10 ton single girder overhead crane adapts well to various tasks within steel fabrication and processing.

- Lower Maintenance Requirements: Fewer components and a simpler structure mean lower maintenance needs and easier servicing — which helps minimize downtime in a continuous operation setting.

- Long-Term Reliability: Built with industrial-grade components and designed for frequent use, 10 ton single girder overhead crane offer robust performance and a long service life, even in harsh steel manufacturing environments.

How 10 Ton Single Girder Overhead Crane Improves Steel Fabrication Efficiency:

- Streamlines Material Flow: Steel fabrication involves moving heavy raw materials and finished products between cutting, welding, assembly, and storage areas. A 10 ton overhead crane allows fast, precise, and repeatable material transfer across the shop floor.

- Reduces Manual Labor and Downtime: By handling heavy loads that would otherwise require forklifts or manual labor, the 10 ton overhead crane minimizes the need for human intervention.

- Maximizes Shop Floor Space: The 10 ton overhead crane operates overhead, freeing up floor space for other operations. This is especially beneficial in steel workshops where space is limited and large equipment or materials are constantly moving.

- Supports High-Precision Lifting: Equipped with advanced pendant or remote control systems, operators can position steel components with high precision. This is essential during assembly, welding, or cutting tasks where accuracy affects product quality.

- Boosts Production Speed: With its 10-ton capacity and wide span, the 10 ton overhead crane can lift large or multiple steel items in a single operation.

- Adapts to Multi-Shift Operations: Designed for frequent use, 10 ton overhead crane can operate efficiently across multiple shifts, maintaining consistent performance.

- Enables Safer Work Environments: Operators can control the 10 ton overhead crane from a distance using remote systems, staying clear of suspended loads and hazardous zones.

- Customizable for Task-Specific Needs: Whether lifting beams, plates, pipes, or frames, a 10 ton overhead crane can be customized with specific lifting attachments or hoists.

Safety Features of 10 Ton Single Girder Overhead Cranes in Steel Plants:

- Overload Protection: Prevents the 10 ton overhead crane from lifting loads beyond its rated 10-ton capacity. Automatically stops operation if an overload is detected, preventing structural damage and accidents.

- Emergency Stop System: Immediate power cut-off function through both pendant and remote controls. Critical for halting operations in case of sudden 10 ton overhead crane failure or unsafe conditions.

- Limit Switches: Hoisting limit switches** prevent over-travel of the hook (both up and down). Travel limit switches** prevent the 10 ton overhead crane from colliding with end stops or walls, reducing the risk of mechanical damage.

- Anti-Collision Systems (Optional): Sensors can be installed to prevent crane-to-crane or crane-to-structure collisions in busy steel yards.

- Load Sway Reduction (Optional Advanced Feature): Helps stabilize suspended loads while in motion, critical when transporting long or unbalanced steel pieces.

- Dual-Control Mode: Pendant + Remote: Enhances operator flexibility and safety. Allows remote operation 10 ton overhead crane from a safe distance, especially useful in high-heat or hazardous areas of a steel plant.

- Emergency Brake System: Mechanical and electrical braking systems engage during power failure or sudden stops to hold the load securely.

- Heat & Dust Protection: Electrical components and motors are often sealed or shielded against heat, metal dust, and sparks — common in steel plants.

Application of 10 Ton Overhead Crane in the Philippines:

- Support for Manufacturing Sector: The Philippines is strengthening its manufacturing base, especially in automotive, electronics, and metalworks. A 10 ton overhead crane is essential for handling heavy components efficiently, reducing labor costs, and improving productivity in factories and assembly lines.

- Infrastructure Development: With the Philippines government’s continued investment in the “Build, Build, Build” program and large-scale infrastructure projects, 10 ton overhead crane are vital in construction sites for lifting steel beams, concrete segments, and machinery.

- Port and Logistics Industry: As a strategic logistics hub in Southeast Asia, the Philippines’ ports in Manila, Cebu, and Davao benefit from 10 ton overhead crane in warehousing and cargo handling.

- Mining and Resource Sector: The Philippines’s mining sector, especially in gold, nickel, and copper extraction, uses 10 ton overhead crane for equipment maintenance, transport of mined materials, and assembly of heavy mining tools.

- Economic Efficiency for SMEs: Many Philippines enterprises are small-to-medium-sized. A 10 ton overhead crane offers a cost-effective lifting solution that balances lifting power and capital investment, supporting business growth without high operational costs.

- Industrial Park Development: The rise of economic zones and industrial parks like Clark and Cavite in Philippines increases demand for heavy equipment. 10 ton overhead crane are crucial in tenant factories for material handling, supporting foreign and local investments.